Applications

It is mainly used for the distillation of zinc oxide, the melting of copper, copper alloy, gold and silver.

Performance Characteristics

- Higher temperature resistance than ordinary isostatic pressing crucible

- More effective against zinc vapour erosion

- Adapts to the strong corrosion caused by chemical additives used in the smelting process.

Furnace Types

Oil furnace, Gas furnace or Coke oven.

Metal Casting Temperature

900-1400℃

Note

If the user originally used clay graphite crucible to distill zinc oxide and now use our company's CD material silicon carbide graphite crucible, since the CD material conducts heat very quickly, it is necessary to reduce the flame temperature from 50 to 100 ° C (depending on the specific situation). Otherwise it may cause the zinc vapor to volatilize too quickly, and it is too late to completely oxidize to zinc oxide.

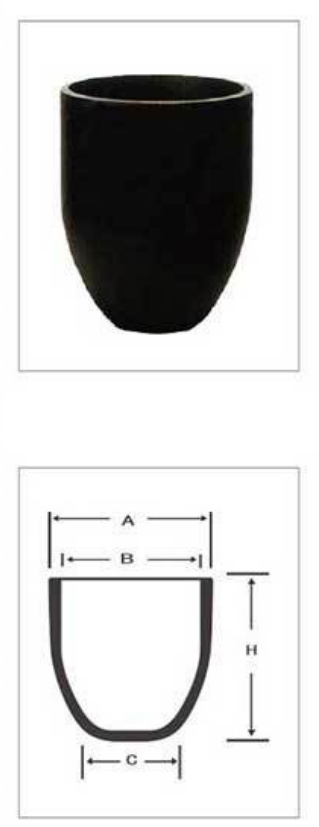

| Size | U0D(A)±5mm | UID(B)±5mm | B0D(C)±10mm | Height ±10mm |

| 26 | 170 | 130 | 115 | 220 |

| 28 | 170 | 130 | 115 | 260 |

| 30 | 205 | 162 | 130 | 265 |

| 40 | 240 | 200 | 170 | 335 |

| 60 | 270 | 210 | 180 | 335 |

| 80 | 290 | 230 | 225 | 340 |

| 85 | 295 | 240 | 225 | 400 |

| 90 | 305 | 248 | 150 | 345 |

| 95 | 310 | 255 | 170 | 345 |

| 100 | 310 | 240 | 220 | 350 |

| 110 | 325 | 266 | 205 | 380 |

| 153 | 375 | 310 | 200 | 400 |

| 154 | 395 | 325 | 220 | 580 |

| 155 | 390 | 330 | 220 | 650 |

| 170 | 355 | 295 | 280 | 480 |

| 200 | 400 | 349 | 215 | 510 |

| 201B | 420 | 360 | 215 | 505 |

| 202 | 425 | 350 | 230 | 530 |

| 203 | 430 | 355 | 230 | 600 |

| 204 | 420 | 360 | 210 | 500 |

| 205 | 430 | 360 | 230 | 650 |

| 292 | 510 | 444 | 290 | 450 |

| 293 | 500 | 444 | 290 | 510 |

| 300 | 450 | 390 | 250 | 500 |

| 339 | 460 | 380 | 220 | 620 |

| 349 | 450 | 390 | 190 | 620 |

| 350 | 465 | 400 | 200 | 700 |

| 353 | 600 | 535 | 340 | 450 |

| 355 | 470 | 400 | 260 | 680 |

| 355H750 | 470 | 400 | 270 | 750 |

| 360 | 460 | 400 | 280 | 681 |

| 364 | 530 | 460 | 310 | 455 |

| 365 | 530 | 460 | 310 | 530 |

| 370 | 530 | 460 | 310 | 570 |

| 451 | 515 | 453 | 280 | 610 |

| 452 | 520 | 444 | 270 | 610 |

| 453 | 530 | 450 | 270 | 680 |

| 455 | 520 | 450 | 278 | 663 |

| 463 | 565 | 500 | 310 | 617 |

| 464 | 580 | 500 | 310 | 617 |

| 501 | 525 | 433 | 255 | 740 |

| 505 | 530 | 445 | 255 | 785 |

| 509 | 540 | 460 | 330 | 610 |

| 511 | 555 | 467 | 327 | 660 |

| 512 | 560 | 467 | 325 | 665 |

| 520 | 510 | 430 | 300 | 760 |

| 521 | 510 | 435 | 300 | 760 |

| 605 | 510 | 460 | 365 | 740 |

| 610 | 550 | 465 | 365 | 785 |

| 650 | 550 | 480 | 421 | 800 |

| 700 | 600 | 503 | 310 | 500 |

| Size | U0D(A)±5mm | UID(B)±5mm | B0D(C)±10mm | Height ±10mm |

| 759 | 600 | 505 | 310 | 530 |

| 760 | 600 | 516 | 310 | 630 |

| 765 | 616 | 534 | 310 | 640 |

| 765H760 | 626 | 546 | 346 | 760 |

| 780 | 580 | 500 | 330 | 880 |

| 790 | 640 | 556 | 310 | 640 |

| 801 | 600 | 530 | 300 | 680 |

| 802 | 605 | 530 | 300 | 710 |

| 803 | 616 | 532 | 320 | 800 |

| 804 | 620 | 532 | 320 | 800 |

| 810 | 620 | 536 | 320 | 830 |

| 820 | 700 | 605 | 290 | 520 |

| 830 | 616 | 536 | 360 | 700 |

| 850 | 610 | 530 | 320 | 800 |

| 910 | 710 | 608 | 290 | 600 |

| 1000 | 715 | 616 | 300 | 700 |

| 1020 | 720 | 635 | 440 | 660 |

| 1050 | 716 | 635 | 440 | 720 |

| 1100 | 590 | 500 | 370 | 1130 |

| 1200 | 720 | 622 | 300 | 740 |

| 1300 | 713 | 642 | 440 | 820 |

| 1400 | 765 | 670 | 440 | 650 |

| 1500 | 735 | 640 | 460 | 900 |

| 1501 | 745 | 640 | 300 | 910 |

| 1503 | 750 | 640 | 300 | 910 |

| 1550 | 775 | 682 | 400 | 750 |

| 1551 | 775 | 680 | 300 | 750 |

| 1600 | 775 | 690 | 300 | 750 |

| 1650 | 775 | 680 | 300 | 810 |

| 1800 | 770 | 670 | 400 | 900 |

| 1803 | 770 | 680 | 300 | 900 |

| BN600 | 785 | 694 | 312 | 900 |

| 1804 | 775 | 680 | 310 | 900 |

| 1950 | 835 | 737 | 350 | 750 |

| 2050 | 800 | 710 | 560 | 850 |

| 2100 | 826 | 746 | 290 | 900 |

| 2250 | 875 | 785 | 350 | 880 |

| 2300 | 870 | 765 | 355 | 1000 |

| 2350 | 880 | 784 | 355 | 1000 |

| 2450 | 880 | 770 | 350 | 1050 |

| 2500 | 880 | 775 | 350 | 1140 |

| 2550 | 880 | 786 | 355 | 1100 |

| 2600 | 900 | 785 | 360 | 1140 |

| 3300 | 970 | 870 | 730 | 900 |

| 5000 | 1040 | 920 | 550 | 1320 |

| D350H700 | 430/350 | 255 | 260 | 700 |

| D850H1600 | 850 | 750 | 560 | 1600 |

| D880H1300 | 880 | 795 | 360 | 1300 |

| D980H1500 | 980 | 880 | 450 | 1500 |